وبلاگ تخصصی مهندسی مکانیک

وبلاگ تخصصی مهندسی مکانیک کتاب،مقالات،نرم افزار،آموزش نرم افزار،حلال،جزوات،فیلم،کاتالوگ،پروژه،مجلات،سایت،اخبار،استاندارد،هندبوک، مهندسی مکانیک ،مهندسی مکانیک،کارشناسی ارشد مهندسی مکانیک،دکترا مهندسی مکانیک،مهندسی مکانیک، تلگرام ، تلگراموبلاگ تخصصی مهندسی مکانیک

وبلاگ تخصصی مهندسی مکانیک کتاب،مقالات،نرم افزار،آموزش نرم افزار،حلال،جزوات،فیلم،کاتالوگ،پروژه،مجلات،سایت،اخبار،استاندارد،هندبوک، مهندسی مکانیک ،مهندسی مکانیک،کارشناسی ارشد مهندسی مکانیک،دکترا مهندسی مکانیک،مهندسی مکانیک، تلگرام ، تلگرامدرباره من

با سلام

در این وبلاگ قرار است اطلاعات مهندسی مکانیک توسط اینجانب محمد شکیبایی نسب در اختیار شما قرار گیرد .

ادامه...

پیوندها

- پایگاه خبری فناوری های پیشرفته ایران

- مقالات علمی کنفرانسهای کشور

- اطلاعرسانیشغلی (جاب ایران)

- باشگاه پژوهشگران دانشجو

- انجام و مشاهده کلیه محاسبات فنی و مهندسی

- فرمولها و محاسبات مکانیک

- محاسبات مهندسی آنلاین

- محاسبه آنلاین وزن اشکال مهندسی

- محاسبه آنلاین چرخ دندها

- جدول تناوبی عناصر و توضیح

- محاسبه آنلاین مقدار پیشگرم در جوشکاری

- گروه بندی آنلاین قابلیت جوشکاری فلزات بر اساس خصوصیاتشان

- محاسبه آنلاین مربوط به انواع فرآیندهای جوشکاری

- انجمن قالب سازان ایران

- سازمان جهانی استاندارد

- پایگاه اطلاع رسانی کتابخانه های ایران

- انجمن مهندسان مکانیک ایران

- ایگاه اطلاع رسانی کتابخانه های ایران

- راهنمای همشهری

- باشگاه پژوهشگران جوان

- (ASA) انجمن آکوستیک آمریکا

- (AIA) انجمن صنایع هوا فضای آمریکا

- (AIAC) انجمن صنایع هوا فضای کانادا

- (ARI) انجمن تبرید و تهویه مطبوع

- (AA) انجمن آلومینیوم

- (AAEE) انجمن آمریکایی مهندسین محیط

- (AAES) انجمن آمریکایی انجمن های مهندسی

- (AACC) انجمن کنترل اتوماتیک آمریکا

- (ABMA) انجمن سازندگان بلبرینگ آمریکا

- (ACEC) انجمن مهندسین مشاور آمریکا

- (AISC) انجمن ساخت فولاد آمریکا

- (AISI) انستیتو فولاد و آهن آمریکا

- (ANSI) انجمن استانداردهای ملی آمریکا

- (ASPE) انجمن مهندسی دقیق آمریکا

- (ASTM) انجمن تست و مواد آمریکا

- (ASB) انجمن بیومکانیک آمریکا

- (ASHRAE) انجمن گرمایش، تبرید و تهویه مطبوع آمریکا

- (ASME) انجمن آمریکایی مهندسین مکانیک

- (AVS) انجمن آمریکایی خلاء

- (IMechE) نهاد مهندسین مکانیک انگلیس

- (IISI) انجمن بین المللی آهن و فولاد

- (IMEKO) اتحادیه بین المللی اندازه گیری

- (ISWM) انجمن بین المللی اوزان و اندازه گیری

- (ISA) انجمن بین المللی اندازه گیری و کنترل

- (SAE) انجمن بین المللی مهندسین خودرو

- (SME) انجمن مهندسین ساخت

- (AGMA) انجمن سازندگان چرخدنده آمریکا

- (CMVA) انجمن ارتعاشات ماشین آلات کانادا

- (CSME) انجمن کانادایی مهندسین مکانیک

- (INAE) آکادمی ملی مهندسین هند

- انجمن طراحی پیشرفته

- انستیتوی اندازه گیری و کنترل

- (AWS) انجمن جوشکاری آمریکا

- (AMBA) انجمن انرژی بادی آمریکا

- (ACEM) انجمن مهندسین مشاور مالزی

- (ARAA) انجمن روباتیک و اتوماسیون استرالیا

- (BARA) انجمن روباتیک و اتوماسیون بریتانیا

- (ARAI) انجمن تحقیقات خودرو هند

- (CAE) انجمن مهندسین مکانیک کانادا

- نرم افزار محاسبه کد ASME

- نرم افزار محاسبه استاندارد اروپا و ISO

- نرم افزار جهت تعیین نوع الکترود جوشکاری

- نرم افزار آنلاین پیش بینی میکرو ساختار و سختی در فولاد ها

- نرم افزار آنلاین برای رسم دیاگرام TTT و یا CCT فولاد

- نرم افزار آنلاین برای پیش بینی ریزساختار و سختی ویکرز ناحیه جوش

- محاسبات آنلاین مبدل حرارتی

- تحلیل آنلاین سیستم گرمایش از کف

- محاسبه ضریب اصطکاک با استفاده از برنامه دیاگرام مودی

- Atmospheric Calculator

- Block Wall Calculator

- Concrete Column Calculator

- Concrete Volume Calculator

- Isentropic Flow Relations Calculator

- Normal Flow Relations Calculator

- Open-channel Flow Calculator

- Oblique Flow Relations Calculator

- Properties of Welds Treated as Lines Calculator

- Shaft Speed Calculator

- Torque Transmitted by Clutch Calculator

- Water Pump Engineering

- Energy Conversion Calculator

- آموزش تصویری مقاومت مصالح و استاتیک

- پایگاه اطلاع رسانی مهندسی مکانیک ایران (پاما)

- پایگاه اطلاع رسانی مهندسی مکانیک

- پایگاه اطلاع رسانی مهندسی ساخت و تولید

- پایگاه مجله بین المللی مهندسی مکانیک

- پایگاه مهندسی مکانیک - ساخت و تولید

- وبلاگ مهندسان فردا

- Reynolds Calculator

- Pipe Pressure Loss Calculator

- Venturi Flowmeter Calculator

- Orifice Flowmeter Calculator

- Exit Spout Velocity Calculator

- converter pressure

- انتگرال گیری آنلاین

- وبلاگ مهندسی مکانیک

- انجمن مهندسی مکانیک

- وبلاگ مهندسی جامدات

- خبرهای شنیدنی

- مهندسی مکانیک و تاسیسات ساختمان

- وبلاگ دانستنی ها

- وبلاگ پسر بد

- پایگاه اطلاع رسانی فنی نیوز

- گروه ایران پی آر جی

دستهها

جدیدترین یادداشتها

همه- جزوه عالی از مقاومت مصالح

- کتاب آموزش مدلسازی المان محدود و شبیه سازی در نرم افزار انسیس (ANSYS

- فیلم های فارسی آموزش مقاومت مصالح ۱ (دانشگاه صنعتی شریف)

- فیلم های قالب تزریق پلاستیک

- پاورپوینت تشریح موتور جت

- ماشین مته شعاعی

- آشنایی با شرکت ذوب آهن اصفهان

- دستگاه فلوفرمینگ

- ماشین مته شعاعی

- فیلم های قالب تزریق پلاستیک

- تبریک روز مهندس

- دانلود جزوه طراحی اجزا ۲ دکتر عباس رهی از دانشگاه شهید بهشتی ویرایش دوم

- دانلود کتاب ترمودینامیک سنجل Cengel ویرایش هشتم

- معروف ترین مهندسان مکانیک

- دانلود جزوه طراحی مبدلهای حرارتی

- دانلود کتابچه اصول پایپینگ

- دانلود جزوه ریاضی 2

- فرمان هیدرولیک

- Visual Nastran

- CVT چیست و چگونه کار می کند؟

بایگانی

- فروردین 1396 4

- آذر 1395 2

- آبان 1395 4

- اسفند 1394 1

- بهمن 1394 3

- دی 1394 6

- آذر 1394 6

- آبان 1394 1

- مهر 1394 5

- اسفند 1393 1

- مهر 1393 7

- تیر 1393 7

- اردیبهشت 1393 4

- فروردین 1393 5

- دی 1392 1

- آبان 1392 8

- تیر 1392 2

- خرداد 1392 11

- اردیبهشت 1392 4

- فروردین 1392 6

- اسفند 1391 8

- بهمن 1391 4

- دی 1391 3

- آذر 1391 3

- آبان 1391 3

- مهر 1391 7

- شهریور 1391 16

- مرداد 1391 13

- تیر 1391 7

- خرداد 1391 5

- اردیبهشت 1391 9

- فروردین 1391 6

- اسفند 1390 7

- بهمن 1390 15

- دی 1390 3

- آذر 1390 16

- آبان 1390 19

- مهر 1390 15

- شهریور 1390 24

- مرداد 1390 23

- تیر 1390 34

- خرداد 1390 22

- اردیبهشت 1390 84

- فروردین 1390 249

- اسفند 1389 217

تقویم

فروردین 1396| ش | ی | د | س | چ | پ | ج |

| 1 | 2 | 3 | 4 | |||

| 5 | 6 | 7 | 8 | 9 | 10 | 11 |

| 12 | 13 | 14 | 15 | 16 | 17 | 18 |

| 19 | 20 | 21 | 22 | 23 | 24 | 25 |

| 26 | 27 | 28 | 29 | 30 | 31 |

جستجو

آمار : 1109247 بازدید

Powered by Blogsky

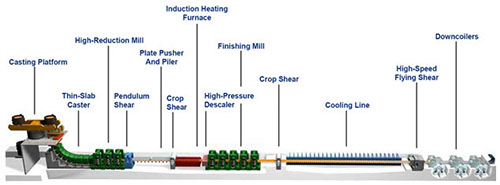

Thin Slab Casting

محمد

چهارشنبه 22 آبانماه سال 1392 ساعت 11:41

برای نمایش آواتار خود در این وبلاگ در سایت Gravatar.com ثبت نام کنید. (راهنما)

ایمیل شما بعد از ثبت نمایش داده نخواهد شد